SYLLABUS FOR EXPORT IMPORT MANAGEMENT

-

GOLDEN RULES FOR SUCCESSFUL BUSINESS

-

PRELIMNARIES FOR STARTING EXPORT IMPORT BUSINESS

-

REGISTRATION WITH GOVERNMENT AUTHORITIES

-

SENDING AND RECEIVING SAMPLES

-

APPOINTING AGENTS

-

PRACTICALLY OBTAINING IEC NUMBER (IMPORT EXPORT CODE (LISCENCE))

-

INSURANCES INVOLVED

-

PRE-SHIPMENT & POST SHIPMENT FINANCE

-

TYPES OF INCOTERMS

-

FOREIGN EXCHANGE

-

INSPECTION OF GOODS

-

LABELLING & PACKING

-

EXCISE

-

DOCUMENTATION

-

SHIPPING & CUSTOMS CLEARENCE

-

SUBMITTING DOCUMENTS TO BANK FOR ENCASHMENT OF PAYMENTS

-

LETTER OF CREDITS & THEIR TYPES

-

AVAILING FACILITIES & FINANCIAL INCENTIVES

-

FISCAL INCENTIVES

-

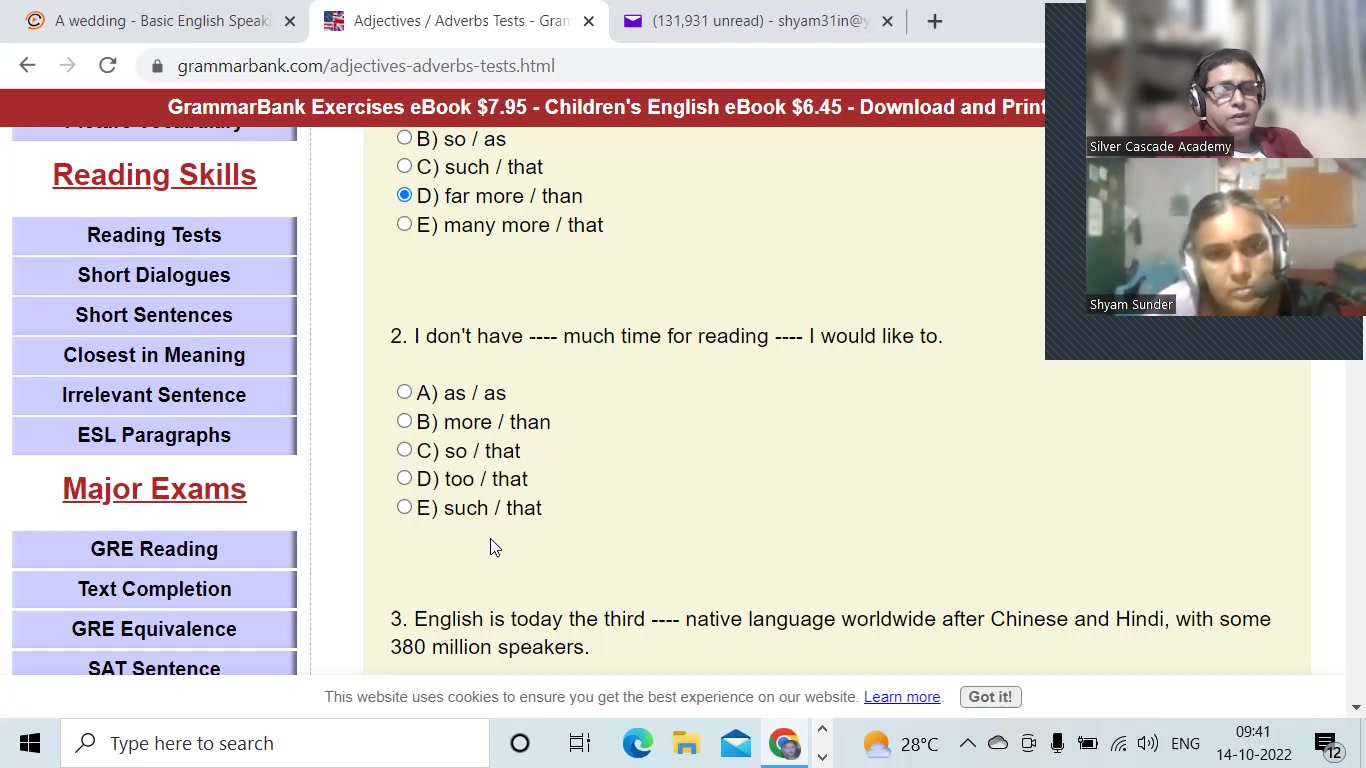

CORRESPONDANCE WITH FOREIGN COUNTERPARTS

- CAN HELP YOU TO GET IEC NUMBER

- I HAVE A SEPERATE COURSE ON GARMENT EXPORT MERCHANDISING WHICH CAN BE DONE ON URBANPRO PLATFORM

-

GARMENT EXPORT WORKSHOP: Role of Merchandiser and his / her interaction with other departments in a Garment Export House

2. Various Departments in a Garment Export House

3. Marketing and Business Development

a) Study of various types of Fabrics and their technical specifications

i) Processes like Printing, Dyeing, Washing,

b) Study of various types of Trims and Accessories

i) Threads (TKT No., TEX No. etc), Types of Stitches, Embroidery etc

ii) Butttons, Studs, Rivets,Eyelets, Snaps

iii) Types of Zippers and various brands

iv) Cords, Piping,

v) Types of Quilting

vi) Types of Interlining

c) How to study TechPack and Bill of Materials from buyer .

d) Arranging Patterns and studying CAD Mini-Marker for consumption of fabrics

e) How to measure a garment

f) How to prepare cost sheet for wovens and knitted garments

g) Correspondance and Negotiations with foriegn buyers

h) Preparation of TNA (Time and Action Calender)

4. After order confirmation:

a) Ordering the fabric (local or imported)

b) Approval of Shade Bands

c) Ordering Trims and Accessories (Local or Imported)

d) Approval of PP sample (Pre-Production sample) and Size-Set to start Production

e) Arranging for Test Reports from agencies like SGS or Intertek or Bureau Veritas

f) Light Box

5. During Production:

a. Preparation of Manufacturing Instruction Sheet (MIS) to be given to Production Manager

b. Arranging for Pilot Run

c. Planning Schedules and asking for Delivery Extensions from buyer well in advance

d. Interaction with Quality controllers (For AQL standards)

e). Ordering Polybags & Cartons

6. Shipment ; Incoterms & Documentation :

a) Study of LCs (Letter of credit)

b) Preparation of Packing List and Commercial Invoice

c) Interaction with Logistics Department & freight forwarders

7. Post Shipment Activities :

a) Aquiring Inspection Reports from buyer’s QC

b) Interaction with Accounts department

c) Preparation of Debit notes if any